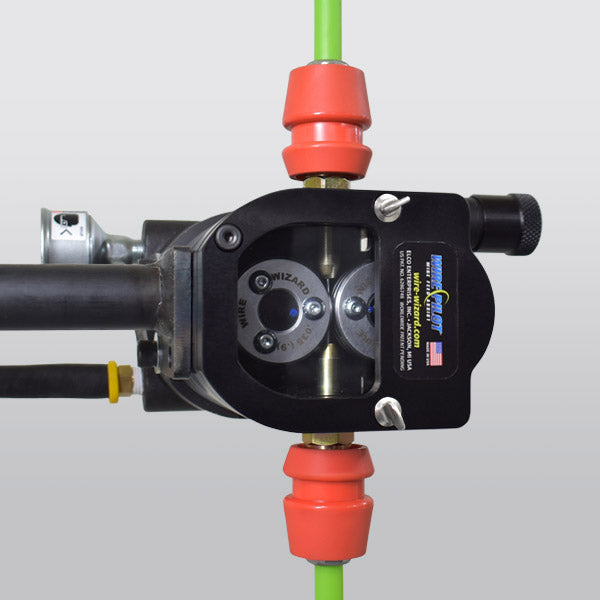

Product Name: Pneumatic Wire Feed Assist

Product Code: PFA-LM

Wire Wizard

The Pneumatic Wire Feed Assist revolutionises welding processes by providing a smooth and less resistant wire feed through the conduit. This innovative technology addresses common challenges in complex wire delivery setups, long-distance wire feeding, and situations where reducing the workload on the wire feeder is crucial.

Designed to optimise welding operations, the Pneumatic Wire Feed Assist utilises compressed air to deliver controlled and consistent force. This advanced system employs a piston or cylinder connected to a feeding mechanism, effectively moving the welding wire away from contact points within the conduit. The result is a seamless guide through the delivery conduit, with adjustable force to meet specific production requirements.

Key Features:

The Pneumatic Wire Feed Assist represents a significant advancement in welding automation. By combining this technology with guide modules, welding operations can achieve unprecedented flexibility in wire delivery. Wire packages can be positioned up to 46 metres or more away from the arc, allowing for the use of bulk wire in applications that traditionally required small spools.

This system effectively relieves several pounds of pulling force from the feed motor, utilising only compressed air. The adjustable torque setting prevents "bird nesting," a common issue in aluminium or light wire applications. The redesigned, compact industrial enclosure offers superior protection against dust and other industrial contaminants, ensuring consistent performance in challenging environments.

Drive rolls sold separately.

Related Products:

Couldn't load pickup availability