Robotic Welding: Premium Peripherals for Precision Performance

SUMIG Robotic Welding components offer unmatched quality & seamless robot integration

SUMIG offers a comprehensive range of robotic welding peripherals designed to optimise performance and ensure seamless integration with welding robots. Each component is engineered for durability, precision and efficiency, making them an essential choice for industries aiming to maximise productivity and weld quality.

Explore our range of options under the categories below:

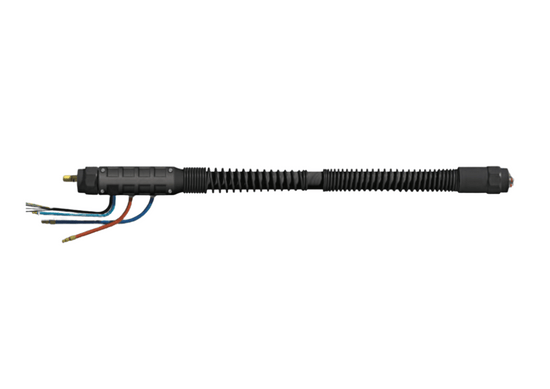

Cable Assembly: Reliable Connections for Optimal Performance

SUMIG cable assembly options are designed to deliver consistent and uninterrupted power and signal transmission. Built with high-quality materials, these kits withstand demanding robotic welding environments while minimising downtime. The robust construction ensures long-lasting performance and compatibility with a wide range of robotic welding setups.

Torch Mounts: Secure & Adaptable Solutions

SUMIG torch mounts provide a stable and secure foundation for welding torches. Designed for flexibility, these mounts accommodate different welding positions and robot arm configurations, enhancing accuracy and productivity. Their durable design ensures they remain reliable in high-stress environments, maintaining alignment and performance over extended use.

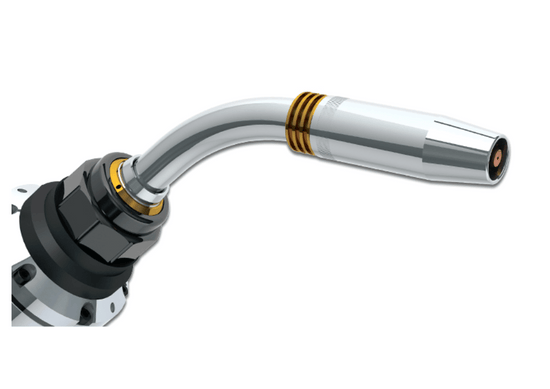

Torch Heads: Precision Meets Durability

The torch head is at the heart of every robotic welding system. SUMIG torch heads are crafted for high-precision welding, offering exceptional durability even under heavy-duty applications. These torch heads are available in various configurations to meet specific welding requirements, ensuring consistent weld quality and reduced maintenance.

Why Choose SUMIG Robotic Welding Peripherals?

SUMIG is dedicated to providing advanced solutions for robotic welding applications. Each component is crafted with precision engineering to ensure compatibility, efficiency and performance. Investing in SUMIG robotic welding peripherals ensures enhanced productivity, reduced maintenance costs and downtime, and a superior weld quality.

Not sure where to start? Reach out to us today to discuss a solution tailored to your needs.